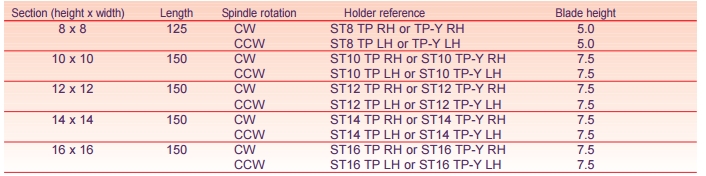

– PARTING – OFF –

ST holders are manufactured from tool steel and hardened to HRc 40. The high precision profile of the blade pocket ensures accurate location. Toolholders are available in LH and RH versions with two types of clamping systems. The TP version provides maximum rigidity for possible turning operations and the TP-Y version places the blade in line with the outside of the holder for absolute closeness to collet when using the appropriate blade width.